At Brunk Industries “making something that no one else can” is a source of pride, and the catalyst for a growing company.

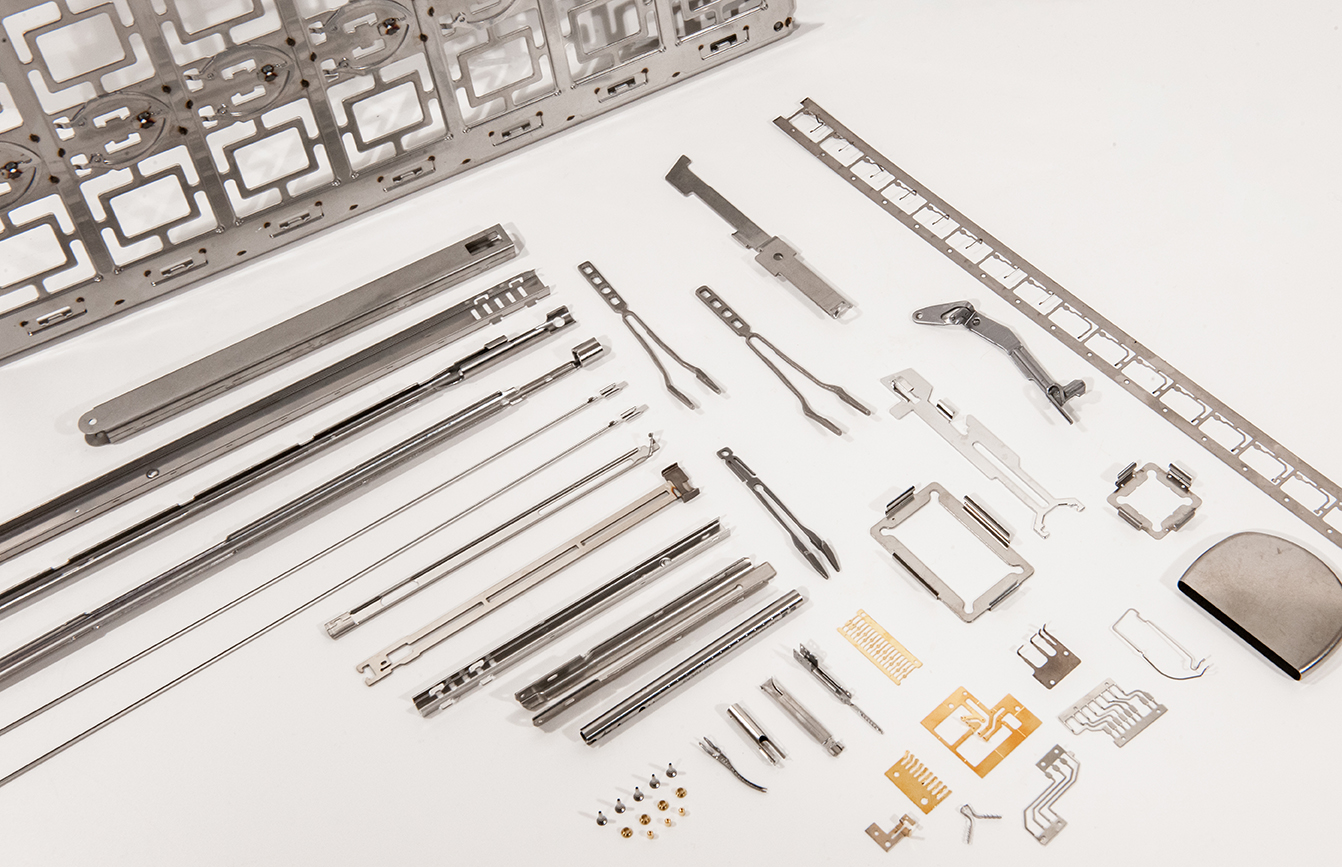

“We look at things and say, ‘How can we take that machined part and convert it into a metal stamping?'” said Lars Brunk, President and second-generation owner at Brunk Industries. “In the medical device industry, we are making things in a metal stamped process that no one else in the world has been able to do.

“It requires the right equipment, the right technical talent and the tool-making skills upfront to make it all happen,” Lars continued. “It also requires the right engineering support, and it’s that vertical integration that separates us from our competitors.”

Founded by Swedish immigrants Bertil and Ulla Brunk in 1960, Brunk Industries has grown from a tool and die shop in the family garage to a world-class producer of micro-precision component stampings, assemblies and related services located in Lake Geneva, Wisconsin.

Building on the foundation established by his parents, Lars Brunk recently oversaw the completion of a 60,000-square-foot addition dedicated to expanded manufacturing capabilities.

The high precision medical device industry is the primary market served by Brunk Industries, however, the company also has a growing portfolio of customers in the aerospace and semiconductor industries as well as continuing to expand its capabilities into additional markets.

Heavily invested in technology and talent, Brunk Industries specializes in the more demanding and intricate stamped parts.

“We don’t want to be a commodity stamper,” Lars said. “We don’t focus on the lower-tech stuff. For our customers, it’s all about driving costs and improving quality, and we believe we can do that through technology. And the only way to do that is to have phenomenal talent.

“We want our customers to look at us as a partner, not a supplier,” Lars continued. “As part of a team, we work together every day. With all of our customers, we’re constantly collaborating, working together and communicating all day long. That’s what makes Brunk a successful organization.”

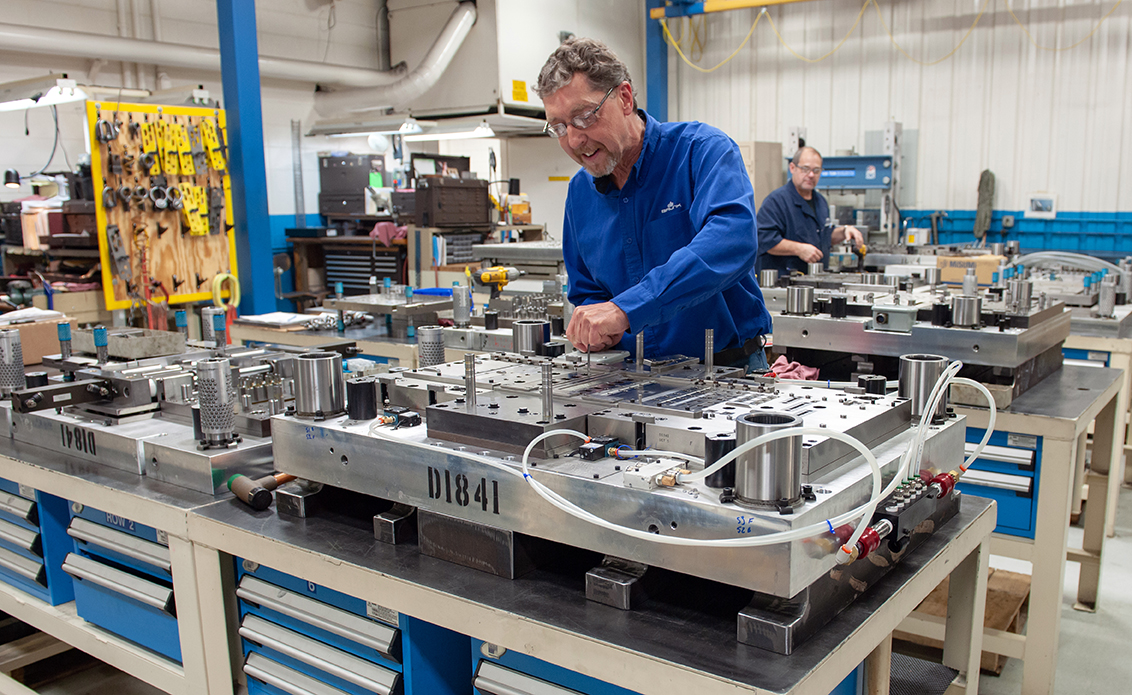

With state-of-the-art prototyping technology and 60 journeyman toolmakers on staff, Brunk gets involved early on in the creation of a customer’s project.

“Tool and die truly remains the heart of our business. We cannot be successful without having the very best in tool and die making skills,” Lars said. “We have a team of designers working with our die makers, and we don’t necessarily wait for a customer to give us a purchase order. We go out and try to prove it ourselves.”

Backing up its new product development capabilities, Brunk Industries features a full suite of value-added assembly and secondary operations.

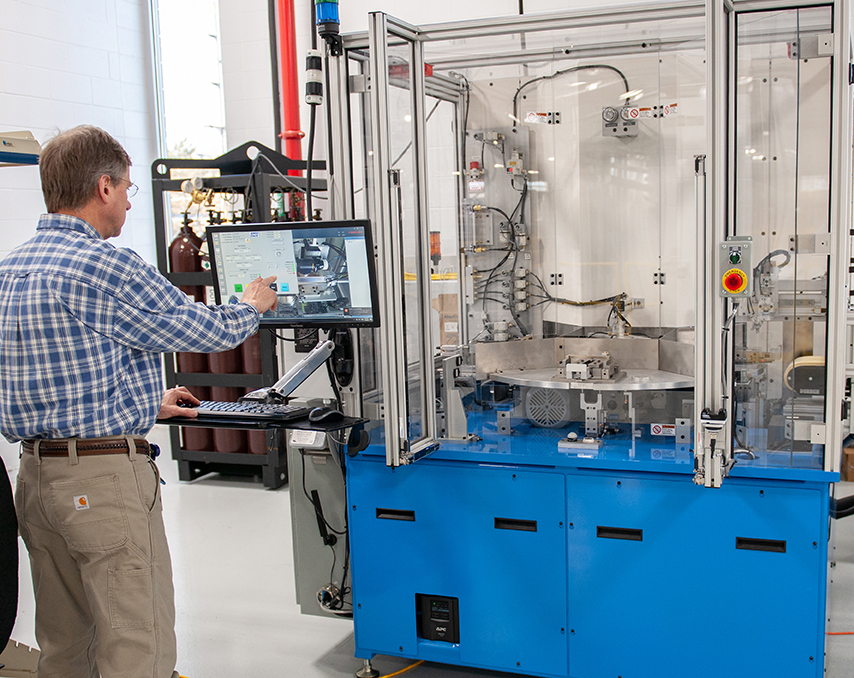

With the recently completed manufacturing expansion, Brunk has greatly increased its stamping capabilities with the addition of a Minster E2-800 Press, a P2H-FX-160 Servo Press and two high-speed Minster P2-100 presses.

All four new presses were installed with Nidec Vamco high-performance servo feeds. As part of the Nidec Press & Automation suite of products, Vamco is a global leader in the design and manufacture of high-speed servo feeding systems.

“The ease of setup, the accuracy and the technology are all very impressive features of the Vamco Feeds, and the reason they were included with our new Minster presses,” said Scott Adams, Vice President of Operations for Brunk Industries. “I’ve always been impressed with Vamco’s products, and because of the increased production speeds, we feel they are just as valuable of an asset as the Minster presses are.”

“I can’t say that we would be considered one of Minster’s largest customers, but they have always been there for us,” he continued. “The relationship grows and continues to get stronger. It’s been wonderful having Minster as a technical partner for Brunk. We wouldn’t be able to do what we’re doing today without the support of Minster.”

Whether it’s setting up a new press or providing technical support, Brunk Industries has utilized the support of Nidec Minster.

“The customer service side has always been great with Minster,” Lars said. “Minster is just like Brunk. We’re both innovative companies and as we look at challenging programs together, I know that Minster will be there to help us. We’re loyal to Minster as evidenced by our relationship that goes back to the ’70s, and I look forward to that continued journey with Minster.”

A WORLD OF RESOURCES

A single-source solution for machinery, service and technology.